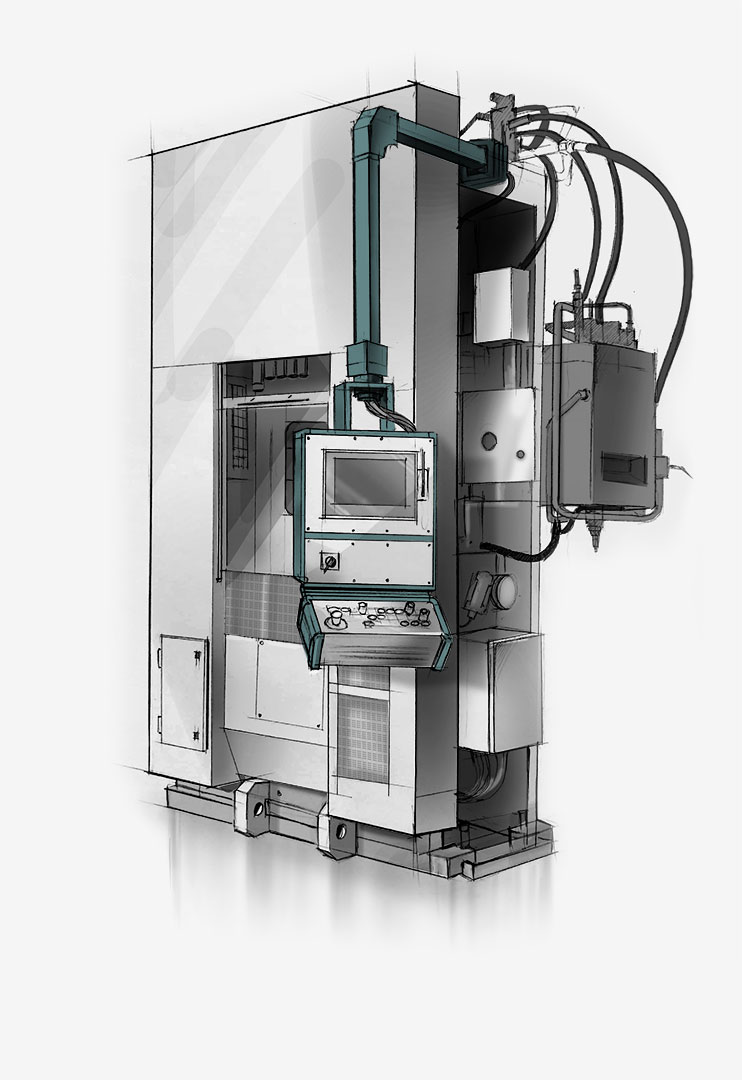

Retrofit

Just like new, but better: The magic word is “retrofit”.

You would like to bring your presses to state-of-the-art technology? Without much effort and without efficiency loss? The PHS GROUP will support you in doing this. With our retrofits, we provide customised solutions for the repair or general overhaul of your existing systems!

The procedure is completely hassle-free for you. We will coordinate the entire retrofitting process with you in advance, adjust the measures precisely to your individual needs and minimize the resulting restrictions for you - in the end, you will have a state-of-the-art system that requires little training and adjustment!

Our primary focus is on economic efficiency: A well-planned retrofit is significantly cheaper than a potential new purchase, but it brings the same productivity and precision with your existing plant, reducing your operating and unit costs in the long term. Contact us now - our experts will develop customised concepts for you in the following areas:

- Modernisation of electrical controls for presses / conveyor system / transfer / removal systems

- Modernisation of the mechanical, hydraulic and pneumatic assemblies (press / conveyor system / transfer)

- Repair welding of the existing machine structure incl. optimisation and, if needed, mobile machining incl. target/actual comparison using a 3D laser scanner

- Modernisation of the automation in the belt conveyor and transfer area

Equipment relocation

From A to B

Equipment relocation can also be part of a retrofit and is, of course, included in our field of activities. We will support you from planning to implementation. After a press inspection before dismantling to identify the actual state, we will carry out the project management and subsequent commissioning, including a safety check after relocation.

With our partners, we will also provide the heavy transport and assembly using lifting equipment as a system supplier.

For you as a customer, this has the benefit of reduced interfaces and smooth commissioning by our service technicians.

Control technology

With our guidance, you are in control!

Easy to operate combined with maximum performance: The control technologies from PHS GROUP guarantee you the maximum possible economic efficiency. Why? This is quite simple: The better the control centre, the higher the productivity of the machines - with means a better cost-benefit ratio for you as the operator!

It is not for nothing that the control system is also called the "heart" of a press. That is why the PHS GROUP employs an entire separate department for the efficient planning and construction of state-of-the-art control systems. Our highly qualified staff will help you discover a previously unimagined potential in your machine, ensure availability and product quality, and better monitor your product quality.

Our team of experts has a comprehensive know-how and is always up to date within the dynamic development of modern control technologies - no matter if they develop the circuit diagram, do the programming or build the switchgear. In addition, we will ensure the future production reliability of your existing control system with electrical retrofits!

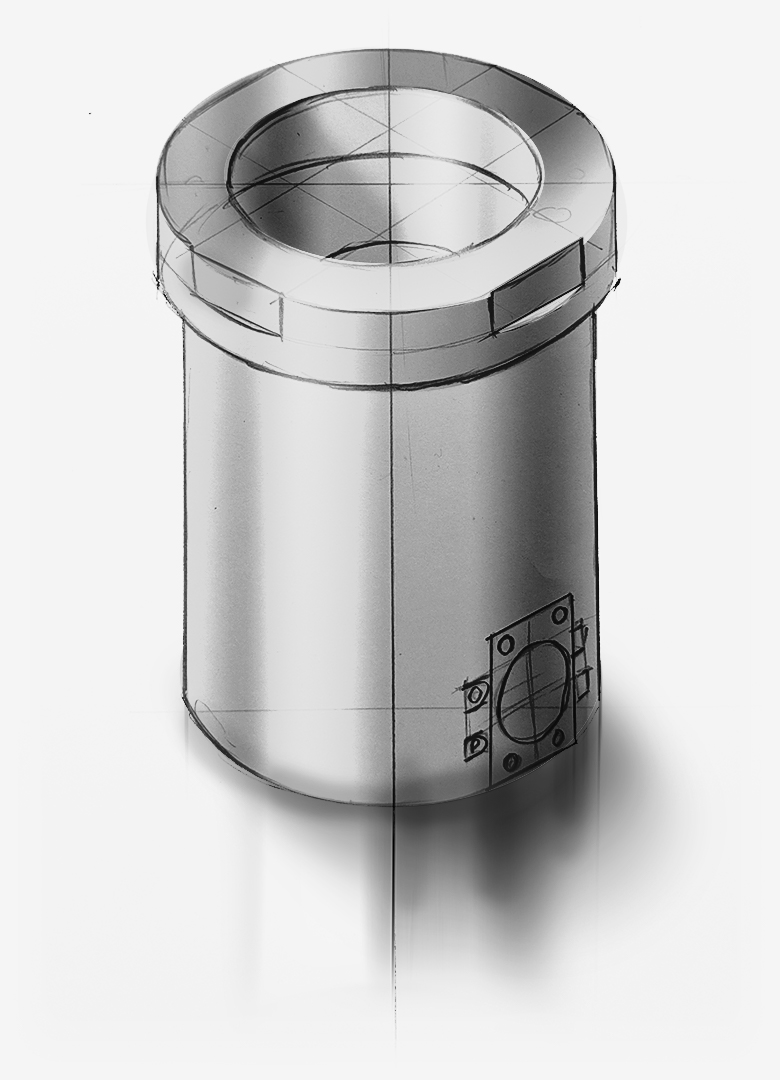

Mechanics

We manufacture everything - from a small spare part to a whole press!

"Everything is possible": We manufacture exactly the components that you need for your machinery - precisely fitting, practical and inexpensive! Thanks to state-of-the-art software, our design team is able to precisely map any mechanical processes of your press using 3D or FEM analysis and to supply every moulded part, no matter how small. Even if the original manufacturer's documents or drawings are no longer available!

For this purpose, our team, which consists of both experts with decades of experience and young engineers with fresh ideas, uses sophisticated reverse engineering methods, which allow components such as plungers or head pieces to be measured in three dimensions and then converted into a CAD model. As a result, also complex assemblies can be analysed, remanufactured and even further developed!

This will not only give you maximum flexibility, but also make you independent of the manufacturer of your press - and in most cases, you even have a considerable price advantage compared to the original parts. Contact us now and arrange one of the following services with us:

- New design or improved design of individual mechanical components

- New design of head pieces, plungers and transmission components such as eccentric gears or countershafts

- Calculation and design of gear geometries, manufacture of the gear components as castings or as a bandage for a repair

- Manufacture of the assemblies including support until delivery and installation

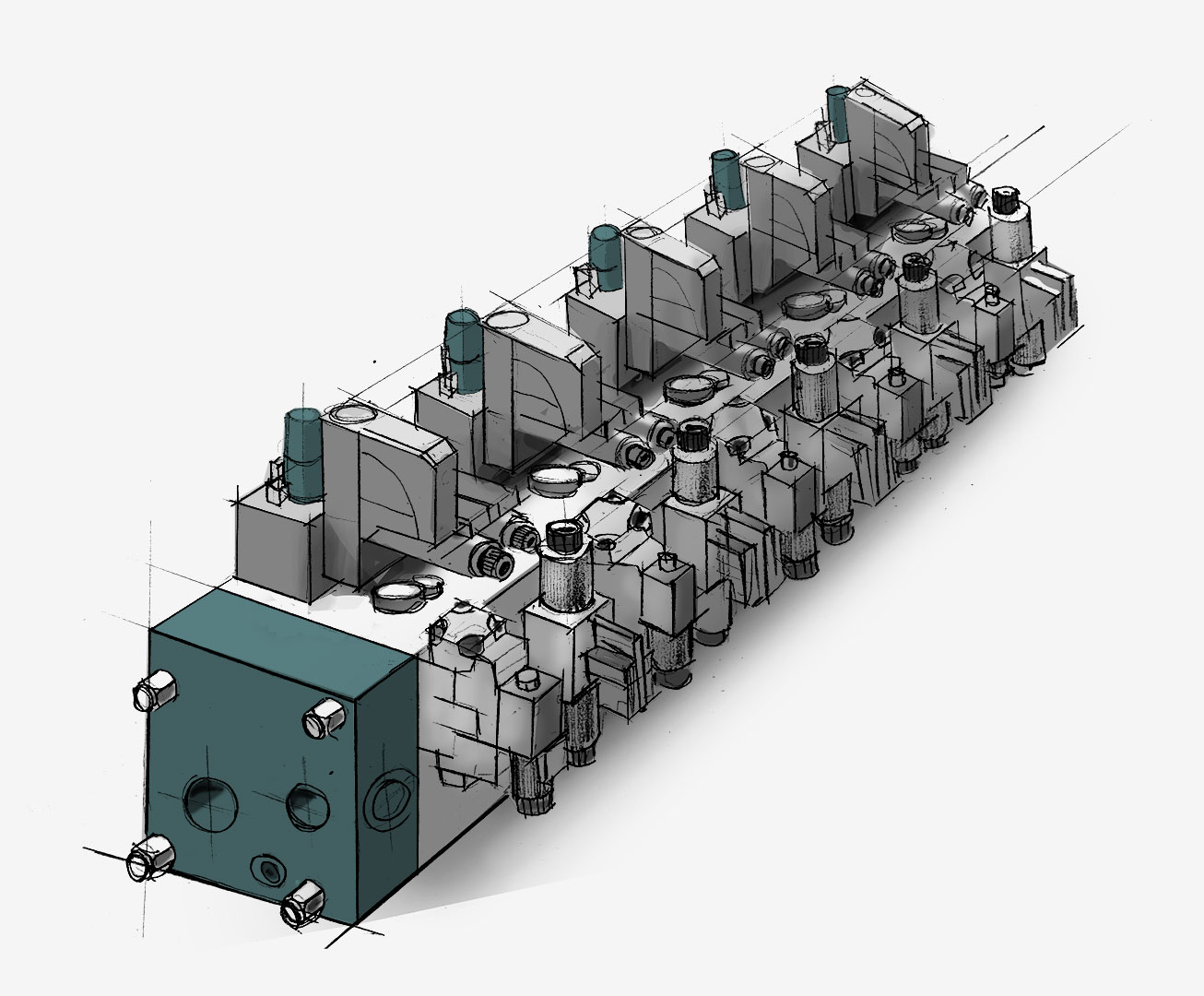

Hydraulics

Your expert in hydraulics

The 'H' is included in our name for a reason: The PHS GROUP accompanies you as an expert partner in the field of hydraulics and fluid technology and ensures that your systems - in the truest sense of the word - stay in the flow! With flexible consulting, analysis and maintenance services as well as high-quality engineering, we ensure the smooth functioning of your equipment and, consequently, the maximum possible efficiency in production.

Thanks to the latest simulation techniques, we can model your existing (or planned) hydraulic system with millimetre precision and thus present you with precisely fitting concepts for maintenance or modernisation at the planning stage. For example, we are able to predict factors such as pressure build-up speeds, pressure peaks or vibrations and use these to determine the properties of the required components.

We also take care of the manufacture of the components, whether individually or in series, such as drive units or cylinders, etc. - we offer you the complete hydraulic service package!

Safety technology

Safety check

We protect people and machines: In order to ensure the proper functioning and safe operation of the presses, the safety guidelines prescribed by law must be followed. Just call us and make an appointment for the annual safety inspection (as per German Accident Prevention Regulations): We identify and eliminate possible risks in terms of occupational health and safety – to ensure that you are safe.

Press inspection

As we all know, the devil is in the detail: This is why we put every single component and the associated structures to a thorough test during the press inspection. Based on this, we create a detailed blueprint - the "fingerprint" of your press, so to speak, which allows us to detect changes in components at an early stage and thus prevent possible damage. On request, we can also carry out the press inspection together with the safety inspection (as per German Accident Prevention Regulations) - to ensure that your press will not stand still one second longer than necessary!

CE conformity

We keep your machine up to date - not only in terms of how it works, but also in the paperwork. Finally, your pressing plant should always comply with applicable standards and directives, first and foremost the CE marking, which signals that the product meets the requirements of the European Community: We conduct this CE conformity procedure for you, prepare risk assessments in accordance with DIN standards and equip older presses with the latest safety technology - so that everything is truly correct!

Trainings

Although the control and maintenance of the equipment, which is serviced by us, is usually maximally user-friendly, only qualified employees should operate the pressing plant. To this end, our team of experts conducts staff training courses that are precisely tailored to your plant: Clearly understandable, scientifically sound and always state of the art - our experts turn your employees into professionals!